Aircraft engine/Gas turbine engine Courses

two courses

Introductory Aircraft Engine/gas Turbine Engine Short Courses

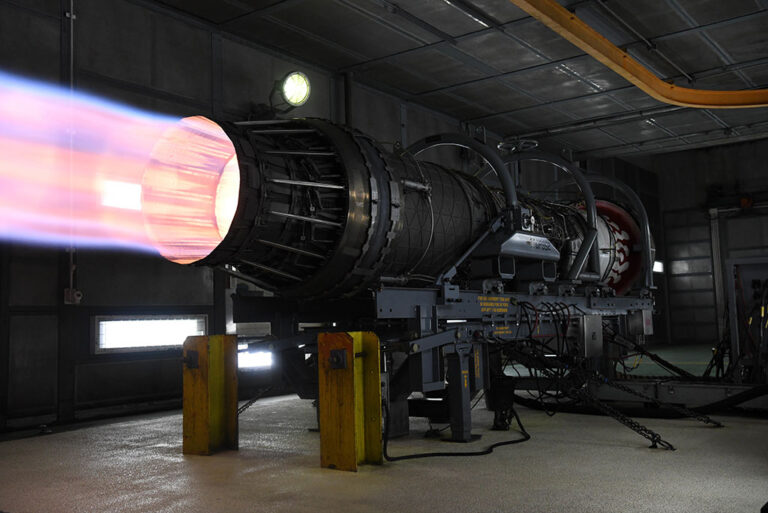

Introduction to Jet Engines

A Practical Perspective

20 hour short course

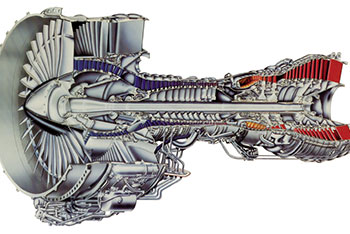

Introduction to Gas turbine Engine Mechanical Systems

A Practical Perspective

20 hour short course

IN AFFILIATION WITH DR. LINK JAW AND WITH EXCLUSIVE RIGHTS GRANTED BY DR. JACK MATTINGLY, Practical Aeronautics is proud to offer the following continuing education courses for those with a technical background!

two courses

Advanced Aircraft Engine/gas Turbine Engine Short Courses

Cycle Analysis of Gas Turbine Engines

36 hour short course

Fundamentals of Aircraft Engine Controls, Accessories and Health Management

36 hour short course

Three courses

Aircraft Engine Systems Design

Our short courses in Aircraft Engine Systems Design (AESD) may be taken individually or as a 3-class sequence. The classes, listed in order of widest audience applicability, are:

AESD – Introductory Systems Analysis (16 hr)

AESD – Intermediate Engine Design (20 hr)

AESD – Advanced Component Design (36 hr)

Individual course descriptions are provided below. These courses will benefit both young and experienced engineers/scientists who wish to broaden their understanding of the strong interplay between design choices, application, and mission. Analysis and design proceeds in response to a simple Request For Proposal (this can be tailored), which specifies the aircraft performance requirements. We have deliberately designed all three courses with this systems-level perspective in mind. Students work in “design teams” which helps reinforce learning. The mutually supportive roles of analytical tools, iteration, and judgment are clearly demonstrated. The methodology employed reproduces the design process of industry and can be applied to many engine types, while allowing for the free substitution of individual design criteria and calculations.

The courses are based on the popular AIAA Education Series textbook “Aircraft Engine Design, Third Edition,” written by Mattingly, Heiser, Boyer, Haven, and Pratt, published in 2018, and its AEDsys software, both of which are provided to the participants, as are course notes. The textbook is the winner of the 2005 AIAA Summerfield Book Award.

Aircraft Engine Systems Design

Introductory Systems Analysis

16 hour short course

Aircraft Engine Systems Design

Intermediate Engine Design

20 hour short course

Aircraft Engine Systems Design

Advanced Component Design

36 hour short course

What’s Special about Practical Aero Courses?

Unique Content Design, Systems Focus,

Unique Teaching Style, Building Block Approach